Mimaki UCJV LED UV Printer/Cutter Series

LED UV Integrated Printer / Cutters

The UCJV family of UV-LED printers offer a versatile 2-in-1 solution that allows printing and cutting functionality within a single unit.

The UCJV150-160 is the entry-level print and cut model. It prints up to 13.4m2 per hr and offers high value cost performance. The UCJV300-160 is its high-spec counterpart that delivers 4-layer printing with speeds of up to 25.8m2 per hr.

UCJV Product highlights

- Maximum resolution of 1200dpi.

- 4 print layers (UCJV300-160 only).

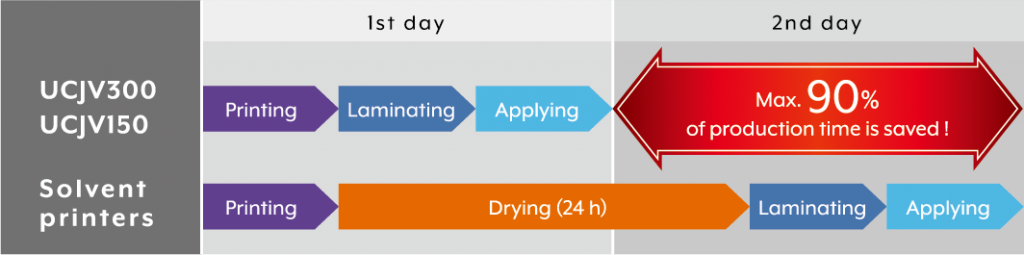

- UV on-demand printing for instant drying and quick next-stage processing.

- Newly developed environmentally friendly UV ink, [LUS-170] and [LUS-175].

- Productive cutting functions with the newly introduced ID Cut improving work efficiency.

- RasterLink6Plus upgraded RIP software.

CMYUK Premium Service eligibility

- Free delivery and installation.

- On-site printer operator training with our certified engineers.

- Free unlimited update training at our Shrewsbury training centre.

Single graphic, dual viewpoints

4-layer printing – for example, colour, black, white, colour – is available on the UCJV300-160 model and offers an enhanced print capability that allows designers to build layered, transformative graphics for backlit applications. This gives print service providers the opportunity to offer something unique – a dynamic graphic that ‘morphs’ its image or colour scheme depending on the light source. This distinctive capability enables designers and print service providers to produce high impact, premium margin output while maintaining low operational costs and reducing production time.

Integrated cutting capability

The integrated cut functionality enables volume production of labels, decals, window clings, floor graphics, POP displays, vehicle markings, packaging, prototypes and more in a single unit. Additionally, UV ink technology prevents common problems such as film separation and other issues related to post-cutting that can occur with solvent and Latex inks.

Instant drying, instant use

UCJV Series prints are cured instantly at the highest production speeds. Unlike other technologies that require slower production to accommodate for drying time or out-gassing, this allows users to print quickly and immediately move to the finished product. For many jobs, instant drying, high scratch resistant UV printing can also eliminate the need for additional finishing like laminating, enabling print service providers to reduce throughput while benefiting from additional cost savings.

Add value with white ink

Combining white and coloured inks on the UCJV300-160 model adds value to applications utilising transparent or semi-opaque films. Compared to alternative inks such as solvent and Latex, UV-curable inks deliver greater opacity with less ink consumption per square meter, whilst maintaining image vibrancy and density. High opacity white ink also facilitates block-out printing within a single print, enabling print service providers to easily and efficiently create window graphics that can be viewed differently from either side, as in a PUSH / PULL door sign. These features ensure higher throughput, reduced waste, and perfectly registered double-sided graphics with lower overhead costs per print.

ID Cut function in RasterLink6 plus software

The UCJV Series printers ship with updated RasterLink6 plus software. This new, feature-rich version of the widely used Mimaki RasterLink RIP software includes an ID Cut function to make printing and cutting easier and faster. The barcode, read by the crop mark sensor on the UCJV printer/cutter, contains cutting and rotation information allowing the UCJV machine to automate the cutting process. This function is particularly useful when running nested print-cut jobs, as the cutter continuously reads the data for both single and combined jobs.

RasterLink6 plus software also includes the FineCut plug-in for Adobe Illustrator, allowing a print preview for 4-layer printing enabling operators to preview the transition day and night effect before printing. RasterLink6 plus now supports PDF 1.5 and above.

Mimaki core advancements

- This printer series utilises Mimaki’s proven base technologies that guarantee superb print quality and continuous productivity.

- Mimaki Advanced Pass System 4 (MAPS4) – utilises an advanced algorithm pattern to reduce visible banding.

- Variable Dot Printing (VDP) – uses smaller drops to produce smoother gradations, while larger drops produce uniform solids.

- Waveform Control (WFC) – uses finely tuned frequencies for each ink’s specific gravity and viscosity to precisely shape and place individual drops.

- Mimaki Circulation Technology (MCT) – continuously agitates white inks to prevent settling.

- Nozzle Check Unit (NCU) – monitors nozzle outages and automatically activates a series of recovery functions.

- Nozzle Recovery System (NRS) – automatically assigns operational nozzles when an outage is detected.

- Half Cut (HC) – a proprietary function where the backing sheet can be cut, leaving behind a small connecting point that can be easily detached when necessary, ensuring contour cut pieces are easier to handle with less waste.

- Over Cut (OC) – makes a crosscut at the start and end positions so the finished piece has sharp edges with no undercut fragments.

- Continuous (C) – crop marks are automatically and continuously detected for accurate cutting.Segment (S) – detects intermediate crop marks in feed direction and enables four-point corrections for each segment for accurate, long-length cutting, even if the image is distorted.

| Item | UCJV300-160 | UCJV150-160 | ||

| Print head | On-demand piezo head | |||

| Print resolution | 300dpi, 600dpi, 900dpi, 1200dpi | |||

| Droplet size | Min. 7pl, max. 28pl | |||

| Head gap | Manual 3 degrees adjustment (2,0/2,5/3,0mm) | |||

| Print speed | 4C Draft mode: 25,8 sqm/h 4C Standard mode: 15,7 sqm/h 7C Draft mode: 13,4 sqm/h 7C Standard mode: 8,0 sqm/h |

4C Draft mode: 13,4 sqm/h 4C Standard mode: 8,0 sqm/h |

||

| Ink | Type | LED-UV ink: LUS-170 | ||

| Colour | 4C(C,M,Y,K) 7C(C,M,Y,K,Lc,Lm,W) |

4C (C,M,Y,K) | ||

| Capacity | 1L (Bottle supply) | |||

| Maximum print width | 1.610mm (63,4in) | |||

| Maximum media width | 1.620mm (63,8in) | |||

| Media thickness | 1,0mm or less | |||

| Media roll outer diameter | φ250mm or less | |||

| Media roll weight | 40 kg or less | |||

| Cut speed | Max.300mm/s (420mm/s in 45 degrees direction) | |||

| Cut pressure | 10-450gf | |||

| Cutter | Types | Eccentric cutter, blade for small character, blade for reflective sheet blade for fluorescent sheet, standard blade for vinyl |

||

| Safety standard | VCCI Class A / FCC Class A / Compliant with UL 60950-, ETL / CE Marking (EMC, Low Voltage Machinery Directive), RoHS/ CB Report / REACH・ENERGY STAR® /RCM |

|||

| Interface | USB2.0 / Ethernet1000 BASE-T | |||

| Power supply | Single phase(AC100 – 120/ 200 – 240V±10%, 50/60Hz±1Hz)x2 | |||

| Power consumption | AC100V: 1.44kW / AC200V:1.92kW ×2 or less | |||

| Operational environment | Temperature: 20 -30 degrees, humidity: 35-65% Rh(Non-condensing) | |||

| Outside dimensions(W×D×H) | 2.900×776×1.475mm (114,2×30,6×58,1in) | |||

| Weight | 188 kg (414,5lb) | 183 kg (403,4lb) | ||

Exhibition Graphics

Floor Graphics

Merchandising

Packaging

Retail POS

Textile

Backlit

Soft Signage

Vehicle Graphics

Wall Graphics